Automatic 2-round field balancing demonstration video

Easiest vibration analyzer and portable balancer

Customisable on request

230V AC or 120V AC or battery operated strobe

Hassle free worldwide shipping

Quick service and support

2 innovative steps towards field balancing

Customer reviews

Easy to use design, faster learning coupled with application specific usage training and reliable customer service is a delight for every technician which made vibration analysis easy for us. We would recommend metro B6012 for vibration analysis and field balancing

metro B6012 downloads

Have a query? Just ask.

Vibration analyzer and balancer features

Know where to add / remove trial weight in first round!

No need to worry about increasing vibrations due to unbalance in second round because operation is performed at point of unbalance in first round.

Automatic machine speed determination from unbalance signal at 1 x machine RPM without requiring tachometer signal using digital FFT techniques.

Find out how it works >

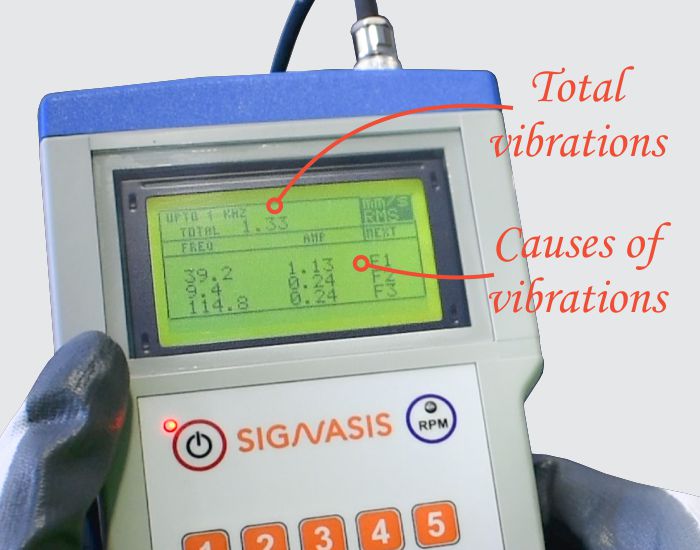

Verify causes of vibrations before field balancing

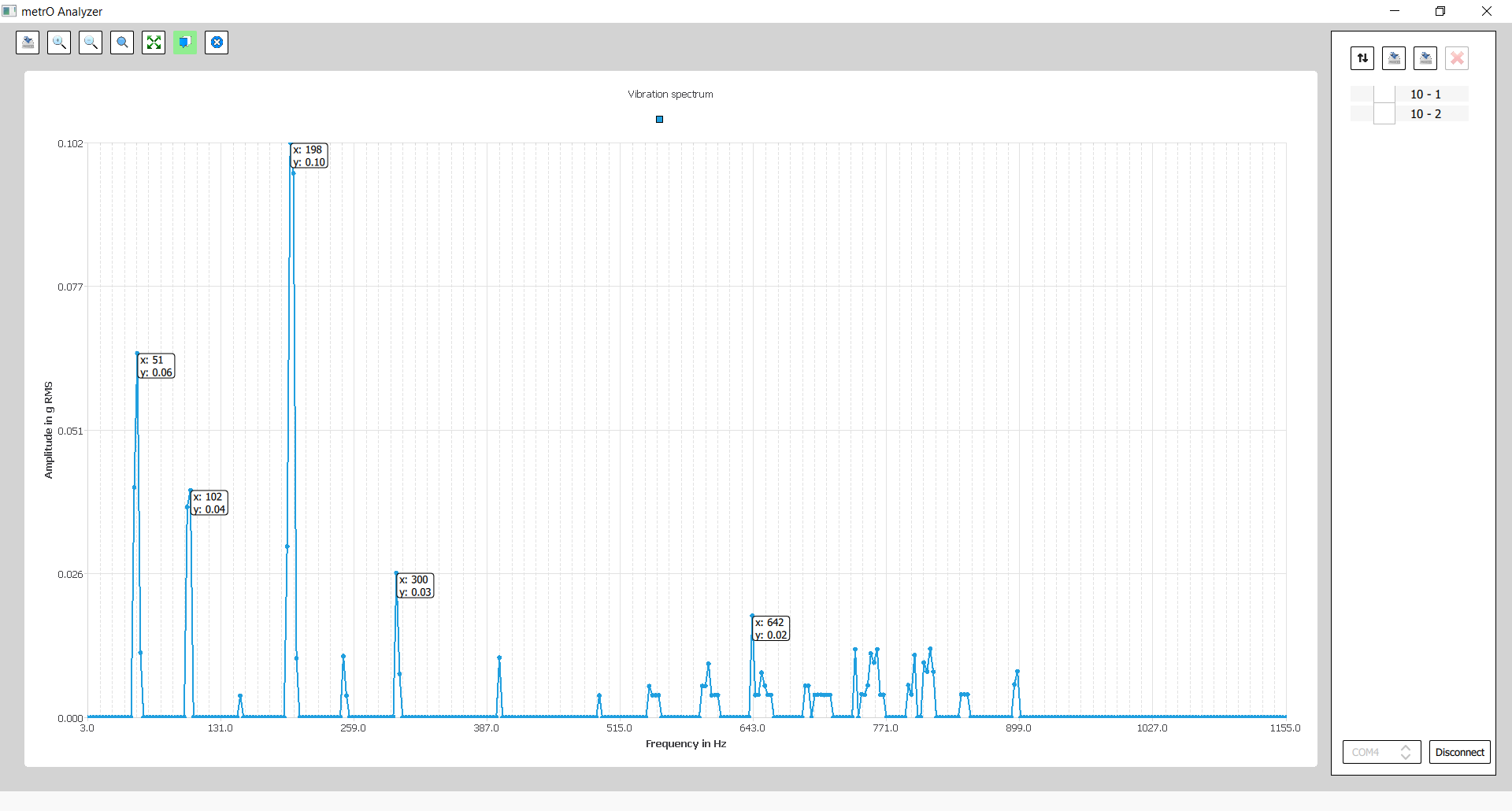

Analyze bearing problems occurring at greater than 3.5 times of machine speed with 12 Hz / 720 RPM of FFT spectral resolution up-to 5000 Hz.

Improved FFT performance with inbuilt Hanning window, overlapping and averaging techniques.

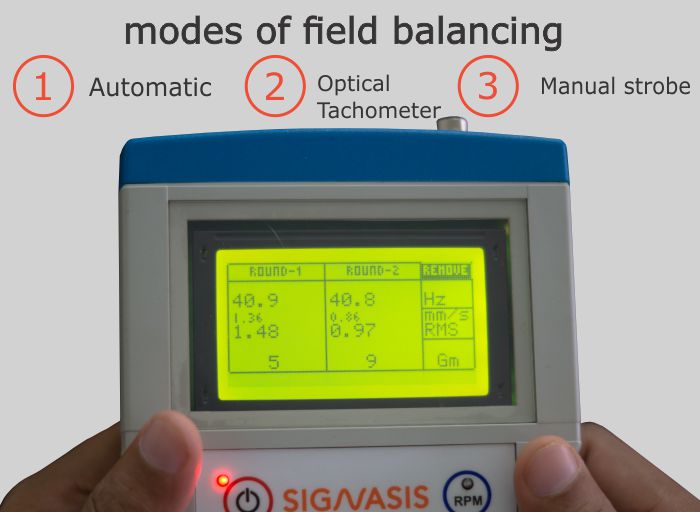

3 methods for field balancing to suit conditions

- When unbalance dominates the vibration spectrum, proprietary Automatic balancing determines machine speed from vibration signal

- Built-in tachometer to get angle of unbalance in degrees

- Manual entry of machine speed is also allowed like the olden days.

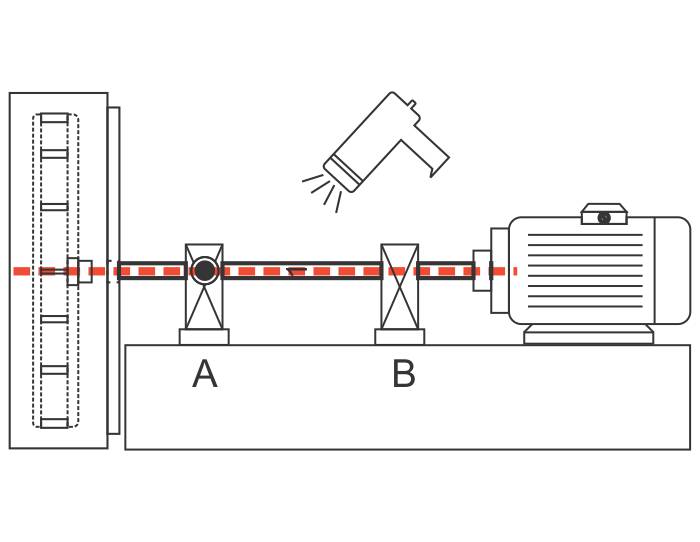

Get your setup ready within 5 minutes

Connect vibration sensor and high brightness stroboscope to proceed with proprietary automatic balancing in minutes.

Pause real-time FFT spectrum for vibration analysis

Frequency zooming for better graphical display resolution.

Hold real-time spectrum update for careful inspection.

Amplitude zooming also possible when viewing saved vibration spectrum data.

Easy to use vibration analysis for beginners and technicians

Better frequency accuracy is achieved through FFT interpolation techniques.

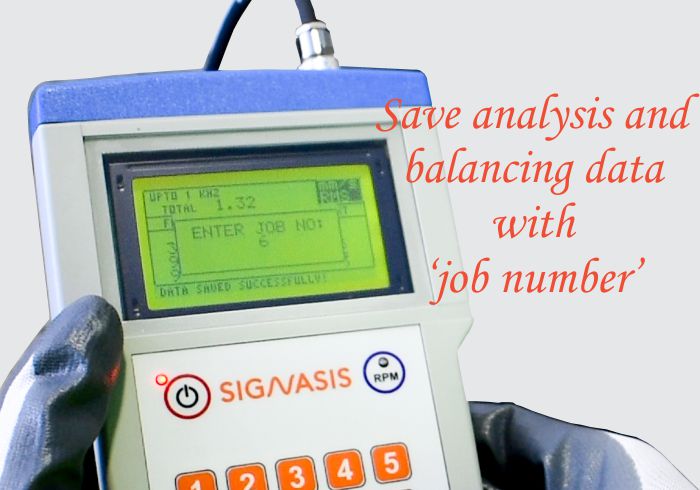

Save vibration analysis and field balancing data per machine

Data is saved as a combination of ‘machine number’ and ‘trial number’ with ‘trial number’ being automatically incremented.

Save multiple vibration spectrum readings with the same machine number for easy vibration analysis.

Connect to computer for data transfer and report generation

Annotate vibration spectrum and save images to generate analysis reports.

Reliable hardware integration for unit conversion

Digital True RMS total vibration level calculation

Constant current accelerometer with shielding for increased reliability

Check comparison of Automatic balancing

|

|

Automatic balancing |

Conventional balancing |

|

Total no. of rounds |

2 |

3 |

|

Reference |

Vibration sensor |

Reflective tape as zero mark |

|

First round |

Exact location of unbalance |

Initial amplitude & arbitrary angle |

|

Second round |

Final weight with exact location of unbalance |

Add trial weight at arbitrary location. New amplitude and arbitrary angle |

|

Third round |

Not required |

Final weight with exact location of unbalance |

|

Removal of trial weight |

Not required |

Required |

|

Location of unbalance |

Exact w.r.t. reference |

Relative w.r.t reference |

|

Unbalance indication |

Visually using high brightness stroboscope |

Angle in degrees w.r.t reference |

|

Ease of unbalance location |

Easy to visually locate location w.r.t. reference |

Difficult to measure angle visually, e.g. 69.5 degrees w.r.t. zero mark. |

Inbuilt tachometer with up-to 70 cm optical range

Point tachometer in-line with the accelerometer to measure angle of unbalance in the direction of rotation in first round of field balancing.

Designed for your safety on-field

No need to mount tachometer near the machine under maintenance where it probably can get damaged.